Longwill- Vape Filling and Capping

Machine Manufacturer

Efficiency and Precision, Saving you More.

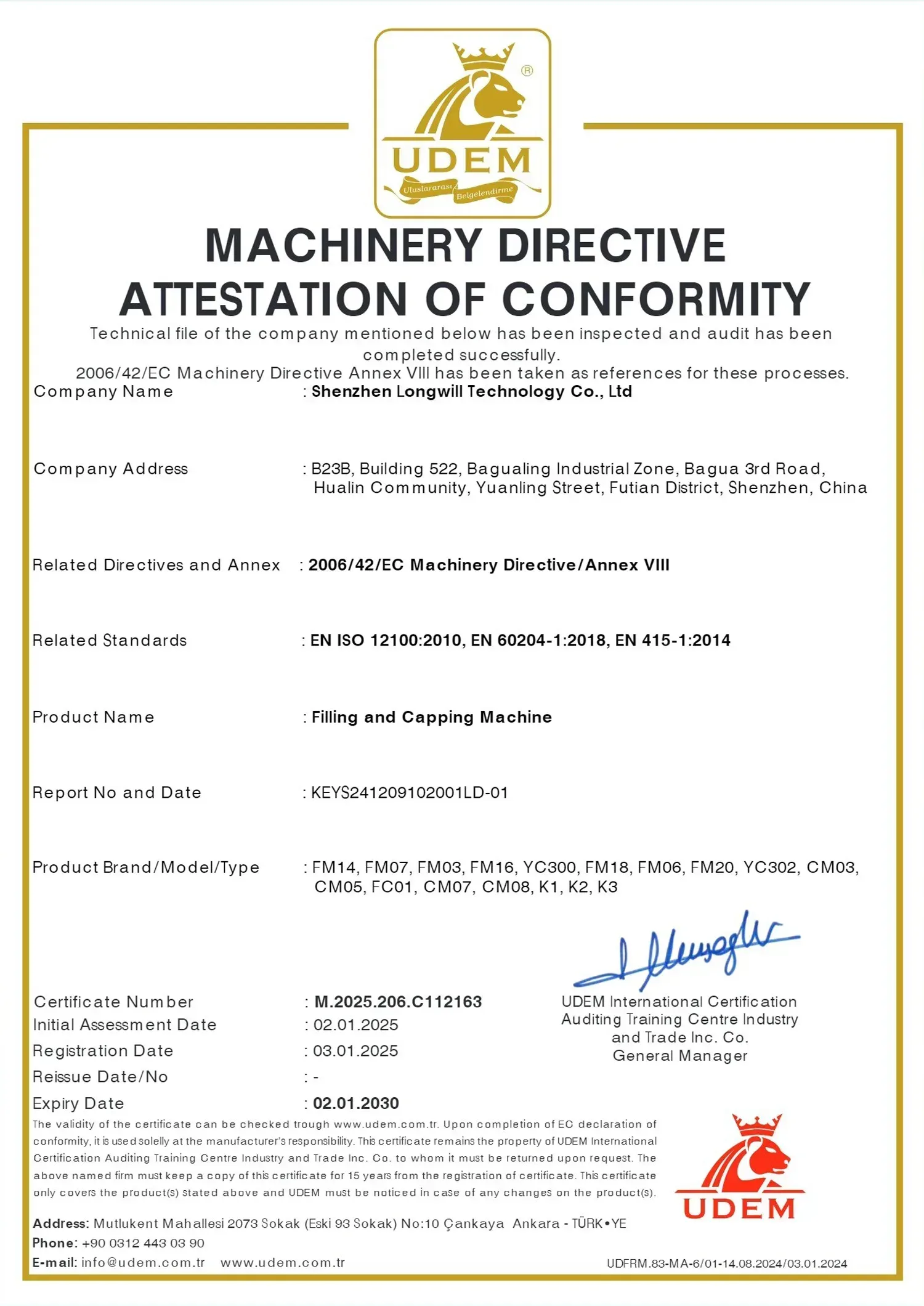

CE FCC Certificated Products

CE FCC Certificated Products

0.01ml filling accuracy

0.01ml filling accuracy

Compatible to 99% disposable cartridges in the market

Compatible to 99% disposable cartridges in the market

10+ Years of Cannabis Oil Filling Experience

10+ Years of Cannabis Oil Filling Experience

300+ clients choose us to improve their filling capping process

300+ clients choose us to improve their filling capping process

Main Product Series

Main Product Series

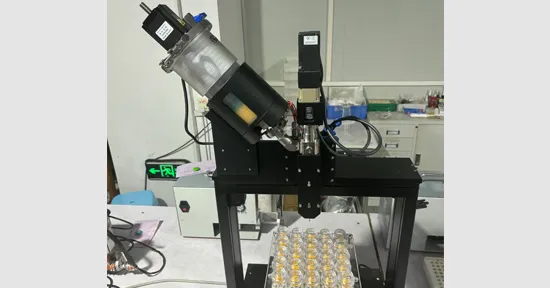

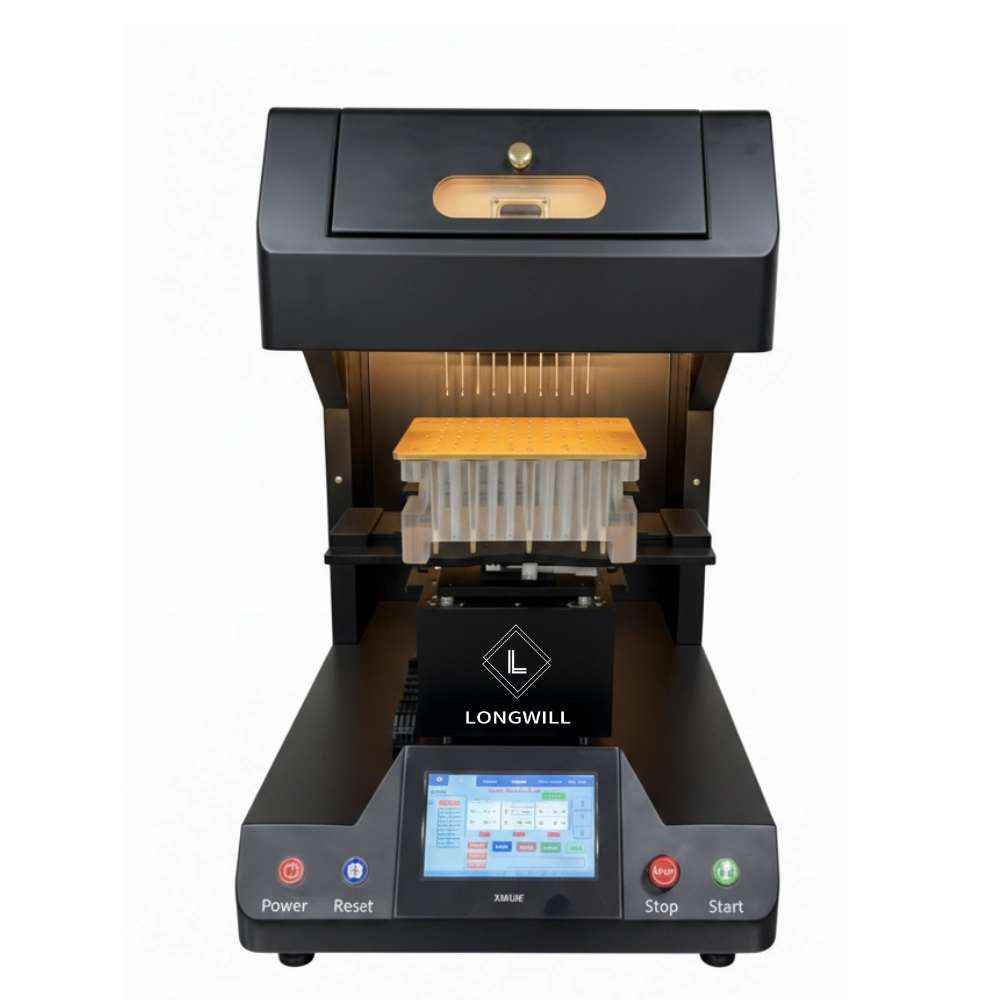

Dab wax filling machine

This dab filling machine is a high-precision, fully automatic solution for thick concentrates like wax and rosin. Built to reduce dripping, it’s a reliable dab making machine for consistent, high-throughput filling in cartridges, disposables, pods, and ja

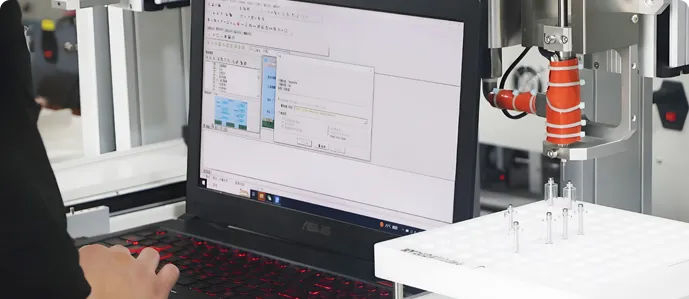

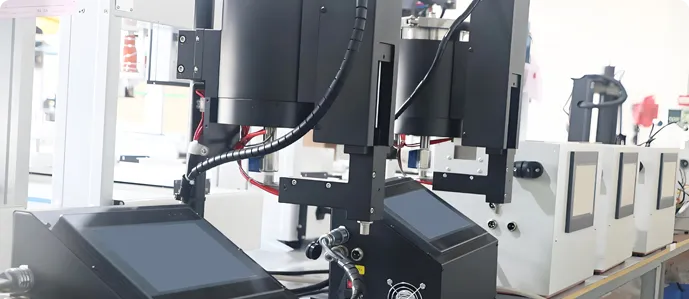

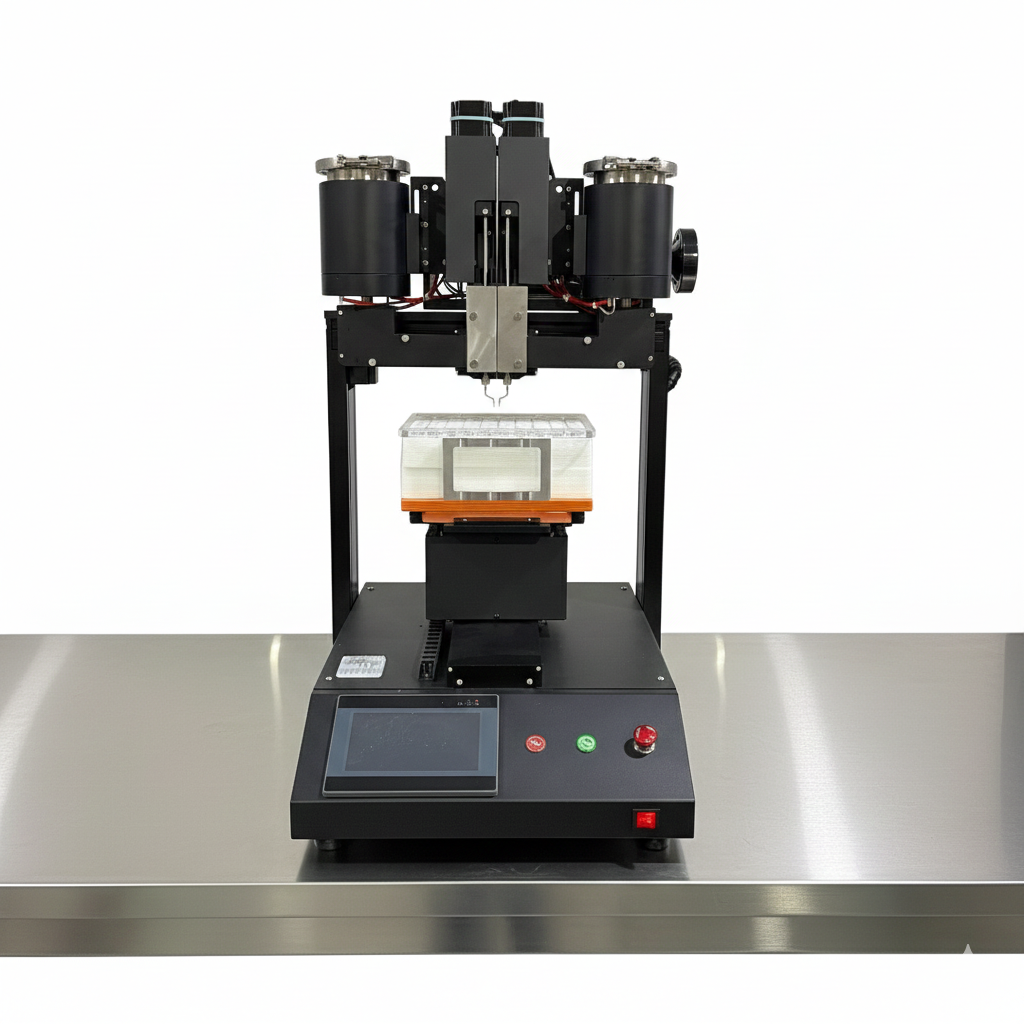

Fully Automatic Dual Oil Tank Cartridge Filling Machine

Fully automatic dual oil cartridge filling machine with dual tanks and nozzles. Supports single flavor and dual flavor CBD vape cartridges with high accuracy.

Amount of oiling: 0.2-7ml + 0.2-7ml

Oil tank: 800ml + 800ml

Oil filling accuracy: ±0.01ml

Output: 800-1200 sticks / hour

Power supply: AC220V/110V

Drive mode: Stepper motor + rail drive

Temperature range: 0-120 celsius

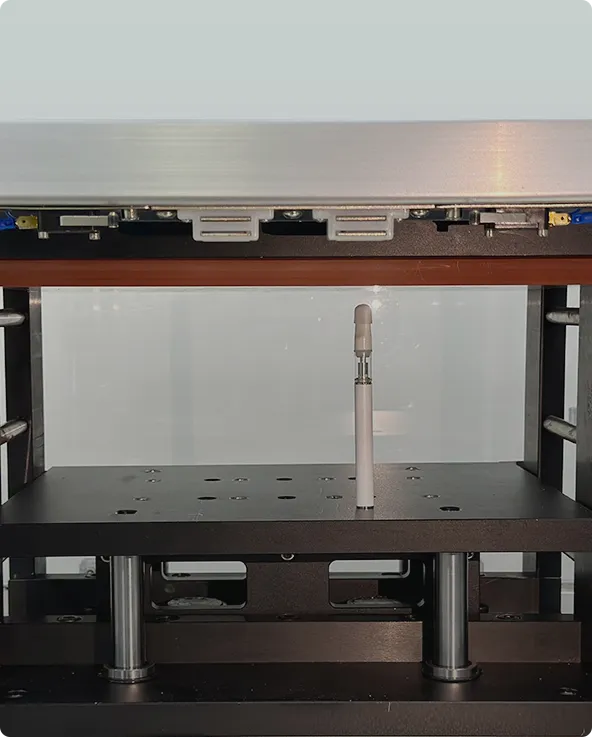

10 nozzle preroll infusion machine

High efficiency 10 nozzle preroll infusion machine designed for infused prerolls. Precise oil dosing from 0.2ml to 1ml. CE & FCC compliant filling solution.

Our Services

At Longwill, we offer more than just filling and capping machine solutions.

We provide comprehensive OEM/ODM services tailored to your needs,

outstanding after-sales support, and fast delivery to ensure your business runs smoothly and efficiently.

About Longwill

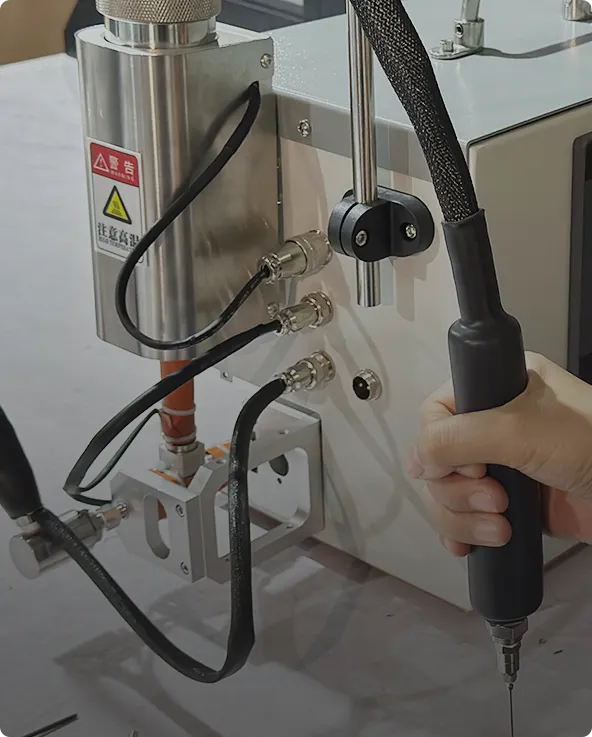

Longwill Technology is a reliable company. We focused on providing high-quality cartridge filling machines, capping machines, pre-roll machines, dab dispenser machines, pre-roll infusion machines and more since 2014.

Our team of highly skilled professionals is dedicated to delivering exceptional products and services that exceed our clients’ expectations. Led by James, our Chief Engineer, who has over 20 years of experience in the machinery industry. we are committed to providing innovative and efficient filling and capping solutions to clients worldwide.

About Us

Our Mission

At Longwill, our mission is to provide innovative, efficient,and high-quality solutions for vape oil filling, capping, packaging, and related services.

Our core values—Efficiency and Precision, Saving you More. This is the heart of everything we do. Both our sales team and R&D experts prioritize these principles, driving us to empower businesses to thrive in an everevolving, competitive market.

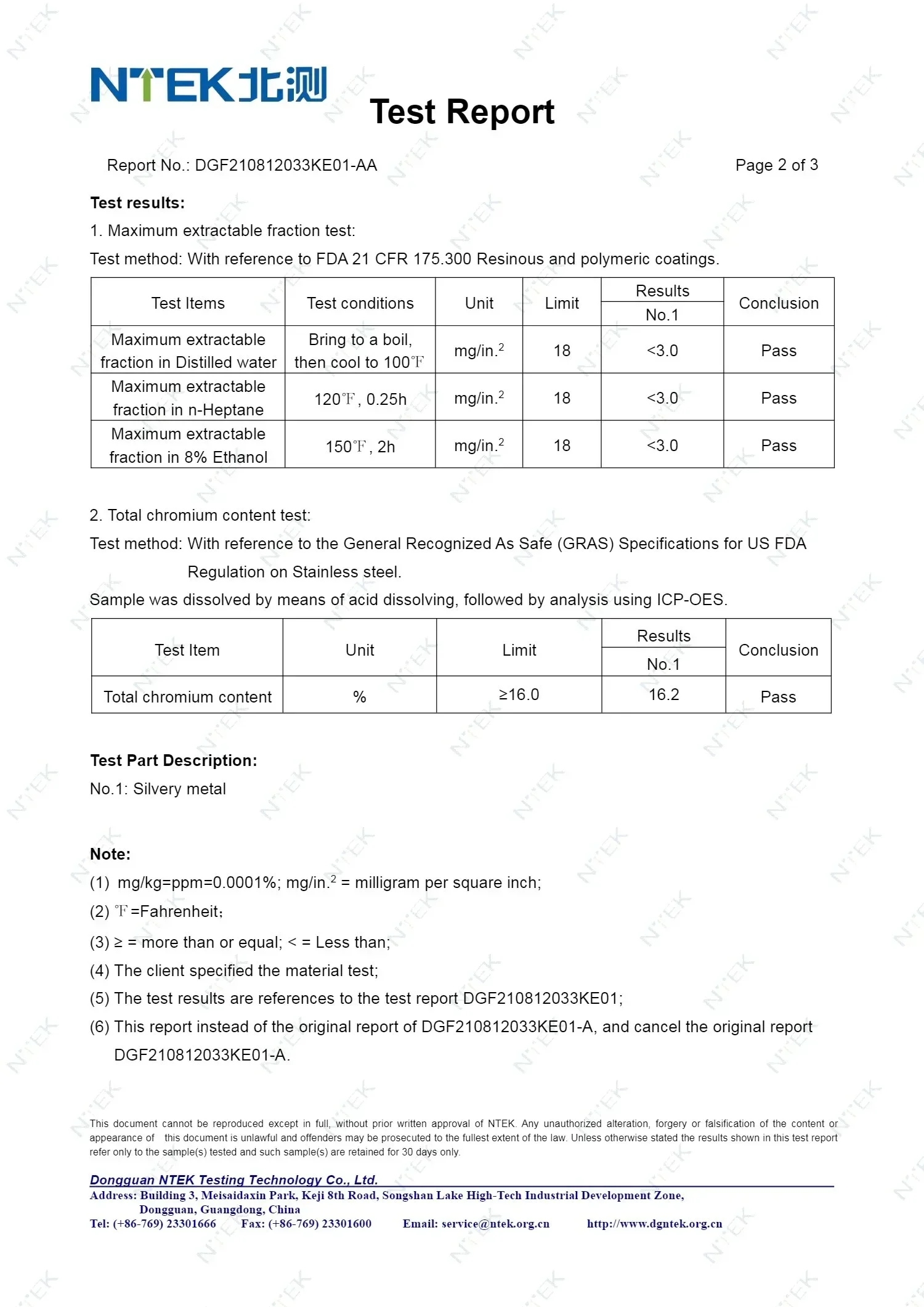

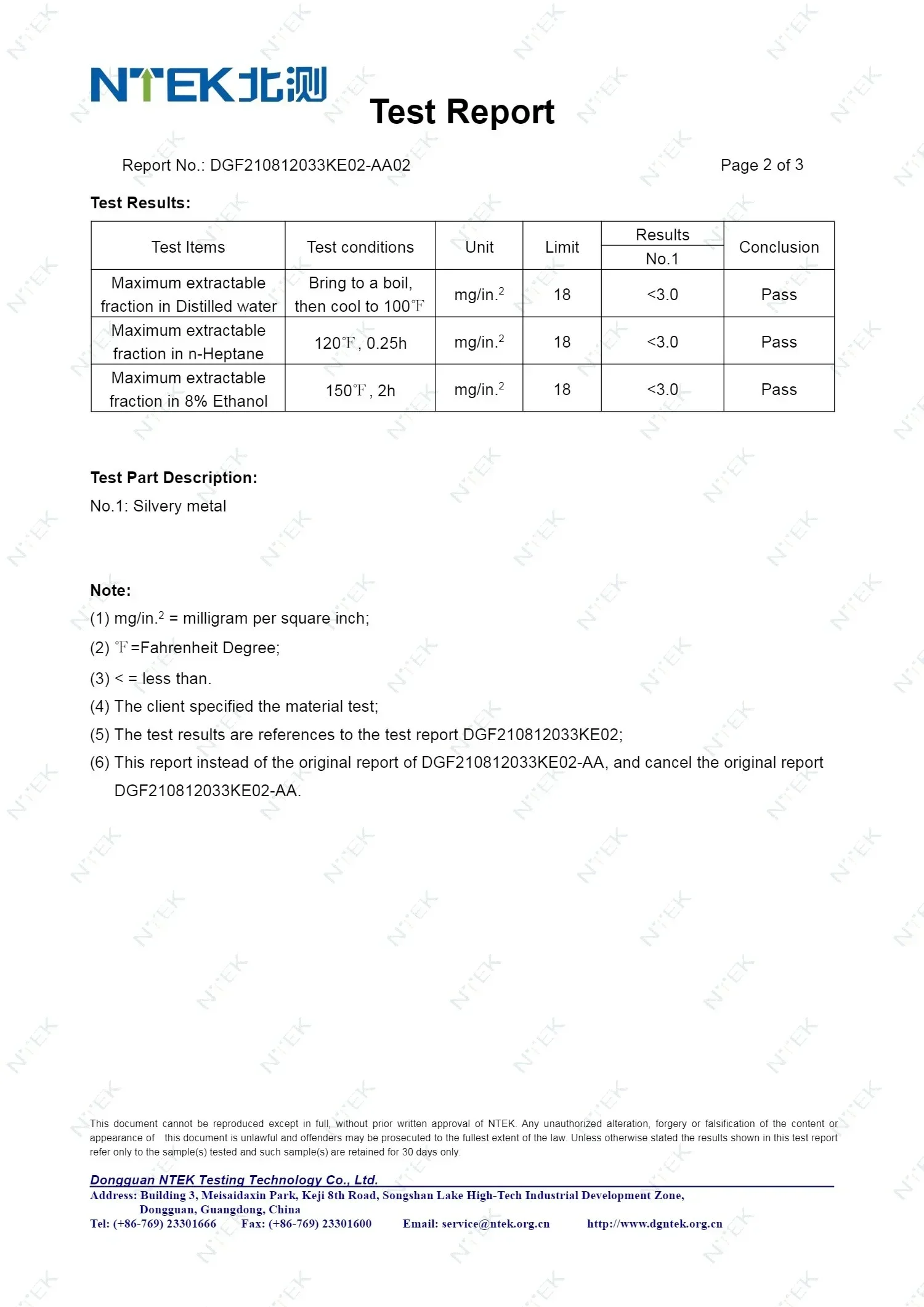

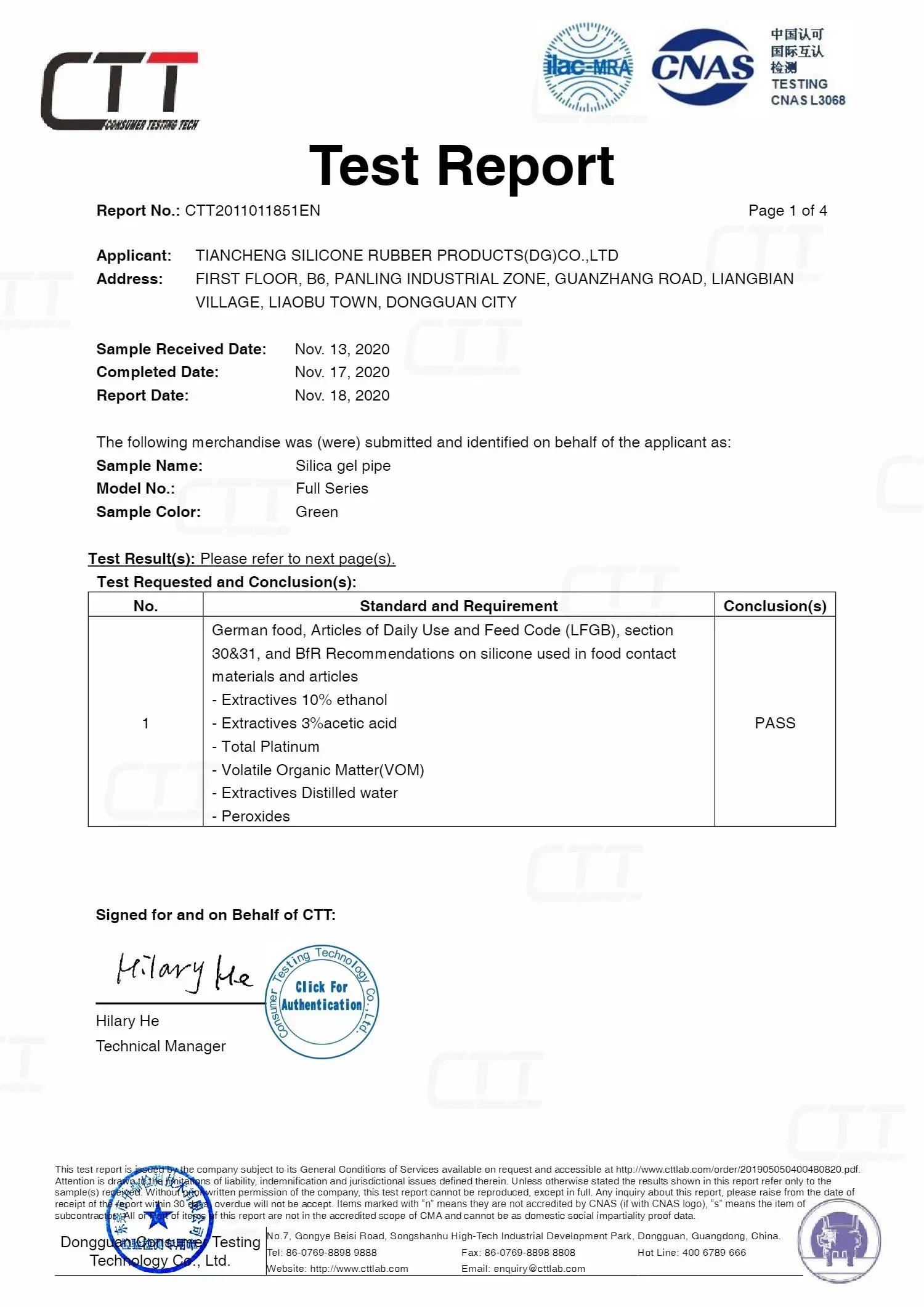

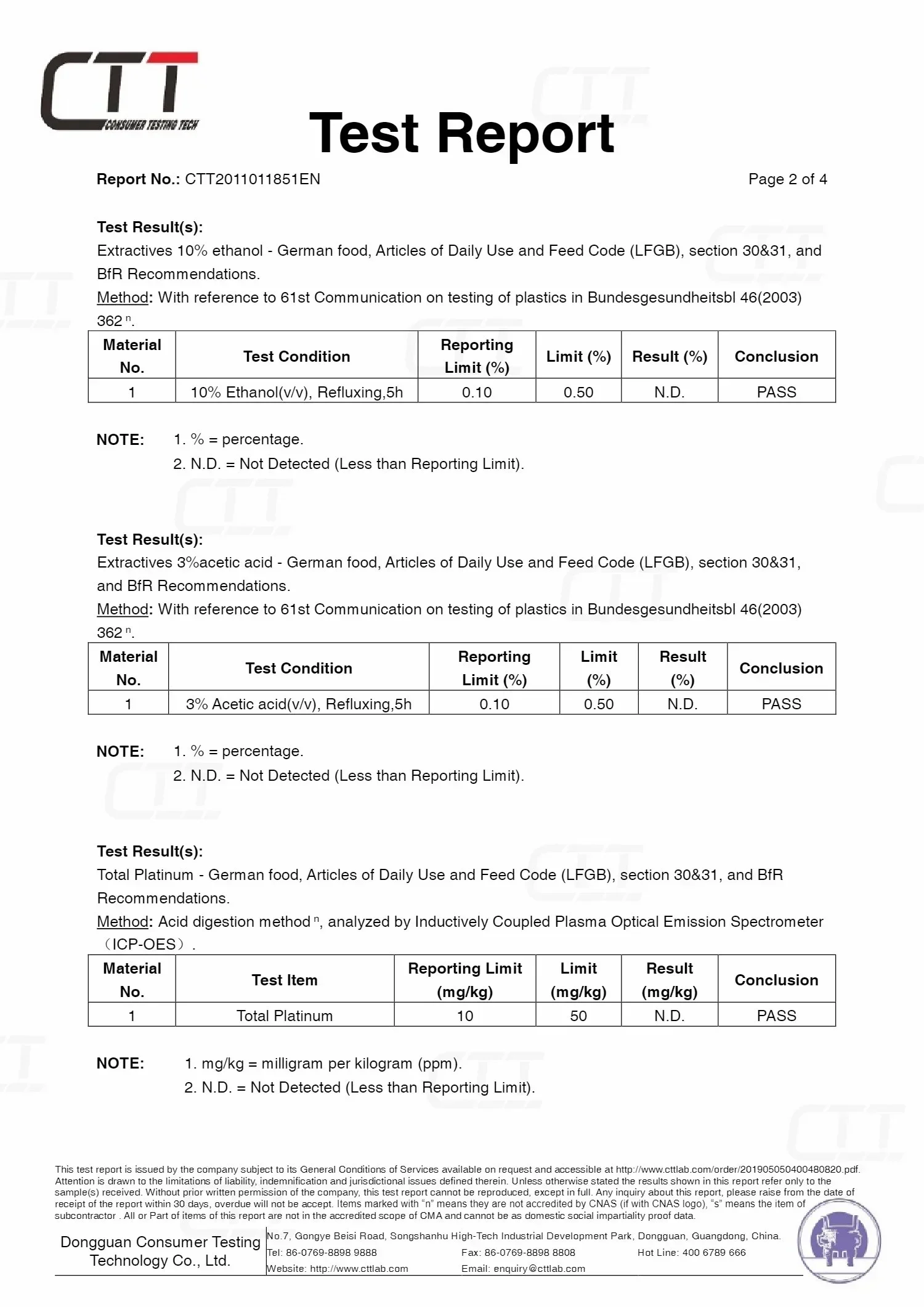

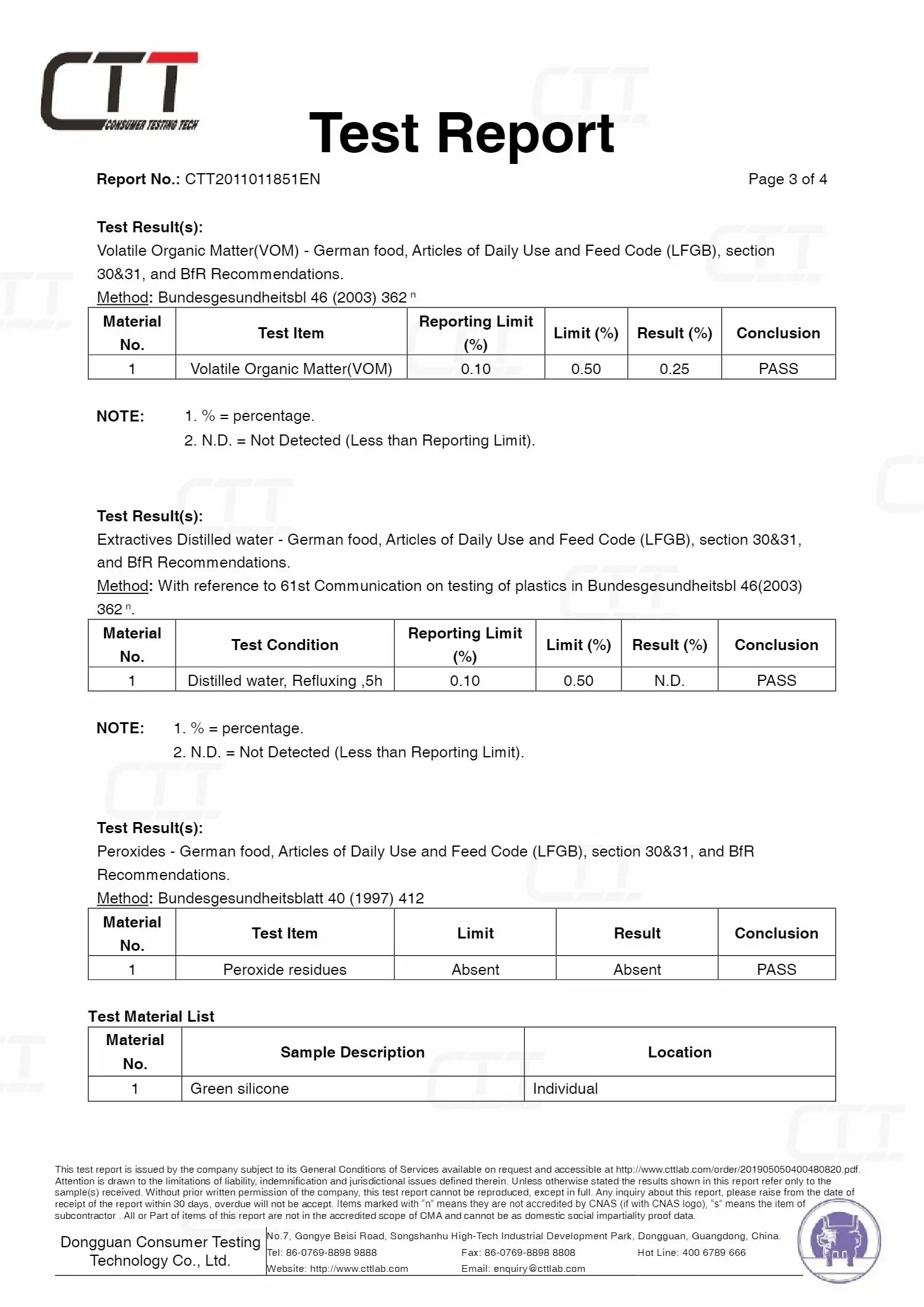

Contact UsCertifications and Honors

All machines have passed CE and FCC certifications, allowing them to be sold in most countries

worldwide. Additionally, the silicone tubing has passed the LFGB

test in Germany, the pumps and

oil barrels have passed the FDA test in the United States, and all materials in contact with the oil are

safe.

Successful Cooperations

Feedback from Customers

Riley Quinn

— Production Manager

"The filling machine we purchased has drastically im-

proved our production efficiency. Its speed and precision are unmatched, saving us both time and material costs. Coupled with fast delivery and excellent after-sales service, your team has been a true partner in our success!"

James Harrison

— Operations Director

"Your capping machine has been a game-changer for our operations. The reliability and accuracy of the equipment ensure every product meets our high-quality standards. The cost savings and seamless integration into our workflow make it one of the best investments we've ever made."

Victoria Clarke

— Plant Manager

"From the moment we placed the order, the entire process was smooth and efficient. The filling and capping machines were delivered quickly, and they exceeded our expectations in terms of speed, reliability, and ease of use. Your after-sales team was incredibly supportive—highly recommended!"

Let's Build Your Product

Unlock the Full Potential of Your Product Development Partner with our expert team at Longwill Equipment to bring your ideas to life. Fill out the form below, and let's take the first step together in turning your vision into reality.

Semi-Automatic vs Fully Automatic Dab Machines: Filling Machine Comparison for Wax & Oil

2025-12-23

In this guide, we’ll compare semi-auto vs full-auto dab machines side by side and break down the key factors that matter most for real-world wax and oil filling. Semi-Automatic vs Fully Automatic Dab Machines: Quick Comparison TableItemVape-Jet Dab Dispenser (Semi-Automatic)Longwill Dab Wax Filling Machine (Fully Automatic)Machine typeSemi-automatic jar filling + weight checkFully automatic dab wax filling machinePrimary useConcentrate jar filling (e.g., 1g jars)Dab/wax filling; supports jars and other formats (with fixtures)Throughput (claimed)Up to 500 x 1g jars/hour2000–3000 sticks/hour (site also lists 20–30 pcs/min)Accuracy (claimed)±1% (with automated weight check)±0.01 ml (site also lists 0.01g)Reservoir / tank1L removable stainless reservoir1L oil tankHeating / viscosity approach“No-to-low heat” + nitrogen-pressurized dispensingHeated system, temperature range 0–120°CControl styleSemi-auto operation; integrated scale + auto-calibrationTouchscreen + PLC; motor/ball-screw controlBest fitBrands prioritizing jar filling + weight validationBrands needing fully automatic precision + higher productivity What Are Semi-Automatic Weed Wax Machines?A semi-automatic dab filling machine is a solid upgrade from hand filling, improving consistency and efficiency while still keeping the operator involved. In most setups, the operator loads and removes containers, starts each cycle, and may verify or fine-tune the fill by volume or weight. Put simply, the dab machine handles controlled dispensing (often with heating), while the operator controls the pace and handling. Semi-auto systems are often chosen for their flexibility. They’re well suited for smaller runs, frequent SKU changes, and jar-filling workflows where quick visual checks and hands-on adjustments are part of daily production. Since the system is typically less complex than a fully automated line, it’s also easier to maintain, easier to troubleshoot, and more budget-friendly. For many teams, a semi-automatic weed wax machine is the practical next step—ideal for moving beyond syringes, supporting in-house dab wax filling, and increasing output without jumping straight into full automation. What Are Fully Automatic Dab Filling Machines?A fully automatic weed wax machine runs the filling process as a programmed sequence, so day-to-day production requires far less hands-on work. In a typical workflow, the operator sets key parameters—fill volume, temperature, speed, and positioning—loads the tray/jig (or fixtures), and starts the cycle. After that, the dab machine handles the rest: it moves into position, dispenses the preset amount, and repeats the same routine across the batch. Many systems add multi-nozzle filling to increase throughput while keeping results consistent from unit to unit. What makes it “fully automatic” is the combination of control and stability behind the scenes. Most machines use PLC + touchscreen control to run repeatable cycles, precision motion components (rails and lead screws driven by a servo or stepper motor) to maintain accurate positioning, and a metered pump system to deliver consistent dosing. For thick wax and high-viscosity oils, temperature-controlled material paths are often included to keep flow steady and help reduce clogging, tailing, or slowdowns during longer runs. Overall, a fully automatic dab filling machine is a strong fit for growing brands that need higher precision, higher output, less dependence on operator technique, and more consistent results across shifts. Key Comparison Points for Wax & OilWhen you’re filling wax, rosin, and other thick oils, the “best” option usually comes down to how well the system manages viscosity, stays stable over long runs, and delivers a clean cut-off. Below are the factors that matter most in day-to-day production—whether you’re using a semi-auto setup or a fully automatic wax weed machine. 1) Viscosity Handling and Temperature ControlA semi-automatic dab machine can handle thick material well—especially if you like hands-on control—but results may vary more with operator pace and technique. Heating is sometimes simpler, such as primarily warming the reservoir. A fully automatic dab filling machine typically holds steadier output because it runs at a consistent rhythm and maintains controlled conditions. Multi-zone heating (tank + line/nozzle) is especially useful for preventing cooling, clogging, and tailing when viscosity shifts during a run. 2) Fill Consistency: Volume vs. WeightSemi-auto workflows often involve more operator checks and may lean on weight verification, which can be ideal for jar filling where weight is the main QC point—though it can slow throughput. Fully automatic wax weed machines usually focus on repeatable dosing cycle-to-cycle; with stable positioning and metered dispensing, they tend to deliver tighter unit-to-unit consistency across larger batches. If you’re scaling, the key is consistency not only at startup, but also after pauses, refills, and longer runs. 3) Throughput and Labor EfficiencyA semi-automatic dab machine is generally much faster than hand filling, but output is still tied to people—starting cycles, handling containers, and keeping the pace moving. A fully automatic weed wax machine is designed to raise throughput without increasing labor at the same rate; once loaded and started, it can run steady batch cycles with less operator involvement. If labor is your biggest bottleneck, full automation is often the clearest path to more capacity. 4) Clean Cut-Off, Drips, and “Tailing”Thick concentrates tend to string, so clean cut-off becomes a major differentiator. Nozzle diameter, heat stability near the tip, pump start/stop control, and repeatable motion all influence whether you get clean breaks or messy tails. Semi-auto can still be clean, but it’s more dependent on operator timing. Fully automatic systems typically synchronize motion and dispensing the same way every cycle, which helps reduce drip variation and keeps results more uniform across the tray. 5) Changeovers, Cleaning, and Multi-SKU WorkflowsSemi-auto weed wax machines can be quicker to clean simply because the systems are often simpler and operators are already working hands-on. Fully automatic machines can also clean up fast when they’re designed with a short oil path, removable contact parts, and easy access to the reservoir and lines. Where full automation often wins is changeover consistency—saved programs and repeatable positioning make switching SKUs more predictable. No matter which route you choose, prioritize easy disassembly, low dead volume, and quick-change nozzles/fixtures if you run multiple products. 6) Flexibility: Hardware and Container CompatibilitySemi-automatic setups feel flexible because operators can adapt quickly to different jars or formats. A fully automatic dab machine can be just as flexible when the platform supports interchangeable trays/jigs, nozzle options, and simple parameter adjustments. If you fill a mix of carts, pods, pens, and jars, look for a system built around fixture swaps and adjustable positioning—not one locked into a single format. 7) Cost of Ownership and Scaling PathSemi-automatic machines typically have a lower entry cost and straightforward maintenance, making them a solid upgrade from manual processes. Fully automatic systems cost more upfront, but they often reduce cost per unit at scale through higher throughput, steadier output, and less labor dependence. If you expect growth in the next 6–18 months, a fully automatic dab filling machine can become the more economical choice once labor savings and production stability start to compound. Read more:https://longwillmachinery.com/Blog/how-does-a-dab-filling-machine-work.htmlhttps://longwillmachinery.com/Blog/how-to-choose-a-dab-filling-machine-for-solventless-concentrates.html ConclusionThere isn’t a one-size-fits-all answer—your best choice depends on your product type, batch size, staffing, and growth plan. A semi-automatic dab machine is often the practical step up from manual filling when you want flexibility and hands-on control, especially for smaller runs or frequent changeovers. A fully automatic dab filling machine is typically the better fit when you need higher output, tighter repeatability across shifts, and less reliance on operator technique.

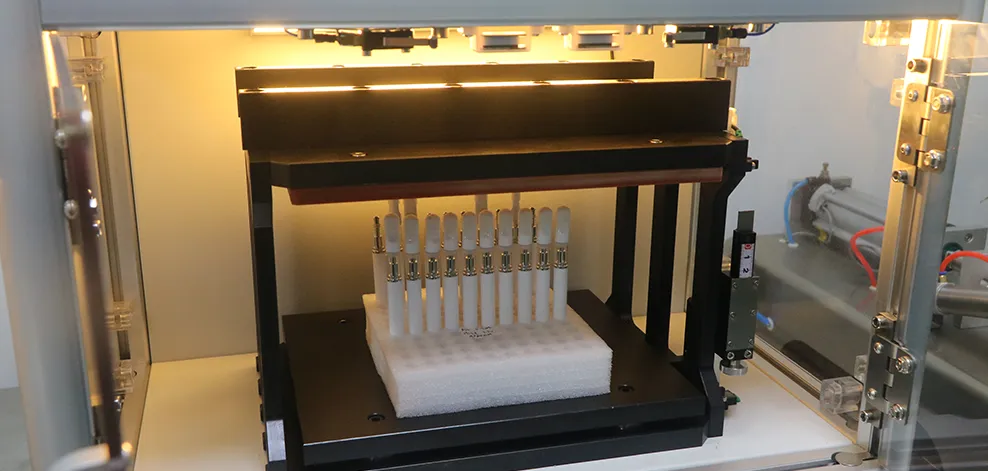

How Does a Dab Filling Machine Work?

2025-12-19

A dab filling machine is one of the most practical tools for turning thick concentrates into clean, consistent finished products—especially when you’re filling cartridges, disposables, or pods at scale. Instead of relying on manual syringes and “by feel” dosing, these machines use programmed control, stable positioning, and repeatable dispensing to improve consistency and reduce waste. Below, we’ll break down what a dab filling machine does, how the filling process works step by step, and what’s happening behind the scenes that makes the workflow truly automatic. What a Dab Filling Machine DoesA dab filling machine is built to dispense precise, repeatable amounts of thick cannabis concentrates—such as rosin, wax, and other high-viscosity oils—into cartridges, disposables, pods, or containers. Rather than relying on hand-filled syringes, it turns the process into a more controlled, consistent workflow, helping each unit come out the same. With accurate metering and steady positioning, the machine helps improve dosing consistency, reduce mess and product loss, and keep batch output uniform. Many models also use temperature control to maintain smooth flow, which can reduce clogging and nozzle “tailing,” making production cleaner and more efficient while supporting better quality control. How a Dab Machine Works Touchscreen setup and parameter selectionA dab machine usually starts with a quick setup on the touchscreen. The operator chooses a program, confirms the target fill volume, and adjusts basic motion and cycle settings—how the head moves, where it pauses, and how the sequence repeats. Once those parameters are saved, the dab machine can run the same routine consistently, which is a big part of how it improves repeatability compared with manual filling. Nozzle alignment over the tray/jigNext, the dab machine moves to the filling station. A multi-needle nozzle head lines up over a tray/jig that holds each unit in a fixed position. The tray does more than keep parts organized—it standardizes spacing and height so the nozzles land in the right place every cycle. That helps reduce misalignment, keeps the work area cleaner, and supports a smoother workflow. In this setup, the machine references practical capacity specs like a 0.2–6 ml filling range and a 2.5 L oil tank, giving flexibility for different products while cutting down on refill interruptions. Multi-nozzle filling for higher efficiencyWith everything aligned, the dab machine dispenses into multiple units at once—5 pieces per cycle in this example. This multi-nozzle approach boosts throughput while keeping results more uniform, since each nozzle follows the same programmed movement and dosing logic. The cycle itself is simple: move into position, dispense the set amount, then lift and reset for the next pass. Because the machine dab workflow controls both motion and dosing, it reduces common manual issues like inconsistent timing, uneven pressure, or slight hand placement differences. Continuous batch filling workflowFrom there, the dab machine runs through the tray in a steady batch routine, repeating the same position-and-dispense sequence until the tray is finished. The workflow stays straightforward: load a tray, run the cycle, and let the machine dab maintain consistent output across the batch. The real benefit is predictability—repeatable alignment and controlled dispensing help reduce under/overfills, minimize interruptions from misplacement, and avoid slowdowns caused by constant manual handling. For growing operations, this kind of steady batch rhythm is often what makes daily production easier to manage and more consistent shift to shift.If you want to view the YouTube video, you can click on it:https://www.youtube.com/shorts/SaWJxKf724I What Makes the Process “Automatic” in a Machine Dab Tray/Jig Positioning (Consistent Alignment)In a machine dab, the tray/jig is more than a place to set hardware—it’s a positioning system. Each cartridge or device sits in a fixed pocket with consistent spacing, height, and orientation, so the machine can return to the same fill points every cycle. That repeatable alignment helps the nozzle head land accurately, reducing missed targets, splashing, and the small placement errors that often create mess and rework during manual filling. Multi-Nozzle Dosing (Higher Throughput)Multi-nozzle filling isn’t only about speed—it also helps standardize output. Instead of filling one unit at a time, the dab machine dispenses into several units simultaneously, increasing output per cycle while keeping the workflow smooth. Because each nozzle follows the same programmed motion and dosing routine, fills tend to be more uniform across the tray. It also cuts down on the constant stop-and-go handling that slows production in single-nozzle or hand-filling setups. Program-Based Control (Repeatable Workflow)What makes the process truly automatic is the repeatable sequence behind it. Operators set key parameters on the touchscreen—like volume targets and cycle behavior—and the machine dab executes the same steps in the same order every time. That consistency reduces guesswork and operator-to-operator variation, which is especially useful when multiple people run the line or when you need the same results across shifts. It also makes changeovers easier because you’re adjusting a known program rather than dialing everything in by feel. Repeatability (Less Variation, Less Waste)Once positioning and dosing are standardized, many common sources of variation drop away—uneven timing, inconsistent pressure, small hand movements, or messy cutoffs. In daily production, that usually means fewer drips and strings, fewer under/overfills, and less product lost during restarts or brief pauses. Over longer runs, repeatability is what keeps yield predictable: cleaner fills, fewer rejects, and less time spent correcting small issues that add up fast. ConclusionA dab filling machine works by combining three core elements: program-based control, precise alignment with trays/jigs, and repeatable multi-nozzle dosing. Together, these features help deliver cleaner fills, more consistent results, and a smoother production rhythm—especially across longer runs and multiple shifts.

How to Choose a Dab Filling Machine for Solventless Concentrates

2025-12-18

In this guide, we’ll walk through the most important factors to consider when choosing a dab filling machine—from pumping and nozzle design to accuracy, scalability, cleaning, and long-term manufacturer support—so you can select a system that fits your production today and grows with you tomorrow. Dab Machines Viscosity ManagementWith solventless concentrates, thickness isn’t fixed—it can shift with the formula, room temperature, and even how long the material sits in the system. A well-designed dab machine should keep product flow consistent so you avoid uneven fills, trapped air pockets, unexpected clogs, or the stringy “tailing” that can leave cartridges messy. When comparing options, prioritize a heated, compact flow path that reduces cooling, a stable metering/pressure system that doesn’t rely on gravity, and—if your oil is prone to separation—an agitation or mixing feature in the reservoir to keep texture uniform from the first fill to the last. Precise, Adjustable Heating for a Dab MachineFor solventless concentrates, heating is really about flow control—it helps the material move smoothly through the system rather than “cooking” the product. What you want is a stable viscosity range so the dab machine can dispense cleanly and consistently from the first unit to the last. In many production setups, thick oils are kept within a moderate working zone (often around 30–60°C, depending on the formula and hardware), so steady temperature holding is usually more important than higher heat. When evaluating a dab filling machine, look for multi-zone heating, such as separate controls for the reservoir and the line/nozzle area, so the oil doesn’t cool and thicken on its way to the tip. It also helps to have fine temperature adjustment and stable regulation (ideally only a few degrees of variation during operation), along with built-in protections like over-temperature safeguards and reliable sensors. Good thermal control makes a noticeable difference on the floor: fewer clogs in the middle of a run, less slowing or pausing, more consistent fill results over long batches, and less product wasted when the line stops and restarts. Appropriate Pumping Mechanism for a Dab MachineThe pumping system is a major driver of fill consistency—especially with solventless concentrates, where viscosity can change as the material warms up or cools down. A reliable dab machine is typically paired with a dosing method designed for thicker oils, such as positive-displacement delivery (often piston-style designs), gear metering, or auger/screw feeding for heavier, more paste-like textures. When comparing options, focus on whether the pump can deliver the same dose repeatedly, stay stable with small viscosity shifts, and start/stop cleanly to reduce dripping, stringing, and messy cut-offs. Be cautious with systems that depend mainly on gravity, produce uneven pressure, or rely solely on timed dispensing without compensation—those setups often drift as soon as the material thickens or the process pauses. Interchangeable, Wide-Gauge NozzlesThe nozzle is where fill quality becomes obvious. For thick concentrates, a wide-gauge nozzle helps reduce flow resistance and lowers the risk of clogging, while a well-designed tip can improve cut-off so you see less drip and tailing. If you run different hardware—carts, pods, and disposables—choose a dab machine with interchangeable tips and quick-change nozzle assemblies. Having spare needles/tips on hand makes changeovers faster and helps keep production moving during cleaning or product switches. Material CompatibilityOver time, solventless concentrates can be hard on certain components—most commonly tubing, seals, and gaskets. For long-term reliability and cleaner operation, look for product-contact parts made from durable, easy-to-sanitize materials (stainless steel is common on contact surfaces), and confirm that the sealing materials are compatible with both your oil and the cleaners you use. It’s also wise to avoid designs that route product through unknown plastics, which can swell, crack, leak, or cause unwanted carryover. Good material compatibility supports everyday performance: it helps protect product integrity, reduces downtime from seal wear, and minimizes flavor or odor transfer when you run multiple products back-to-back. Accuracy and Precision for a Dab Filling MachineFor regulated or premium products, consistency is non-negotiable—and “accuracy” is more than a spec line. What really counts is how the dab machine performs over an entire shift, including after pauses, restarts, and reservoir refills. As a practical benchmark, Longwill machines can achieve ±0.01 ml accuracy, helping maintain tighter dosing control, cleaner batch uniformity, and fewer rejects. When you’re comparing equipment, look for repeatable output across multi-hour runs, stable performance after stop/start events, and straightforward ways to calibrate or fine-tune dosing without turning every adjustment into a lengthy teardown. If small fill swings lead to rework, returns, or compliance concerns, it’s usually better to choose a machine built for repeatability and stability rather than chasing the highest headline speed. Scalability and SpeedPick a machine dab that fits today’s production—and supports where you want to be in the next 12–24 months. Start by defining your real demand: are you filling dozens per hour, hundreds per hour, or thousands per day? Will you begin with a single-head setup but eventually need a multi-nozzle configuration? Are new SKUs or additional device formats part of the roadmap? A strong platform lets you scale without starting over. Look for modular upgrade paths (adding nozzles/heads, stepping up automation), consistent performance at higher cycle rates, and a design that expands with your workflow instead of forcing a full replacement as volume grows. Ease of Cleaning and MaintenanceSolventless concentrates are sticky by nature, and cleanup time can quietly become a major operating expense. A machine that looks fast on paper can feel slow in reality if changeovers are messy, disassembly takes too long, or residue builds up in hard-to-reach areas—especially when you switch products frequently. Prioritize designs with easy access to the reservoir and flow path, fast disassembly for routine cleaning, minimal “dead zones” where oil can settle and harden, and readily available consumables such as seals, nozzles, and filters (if used). In daily production, faster cleaning and smoother changeovers often deliver more value than a small bump in cycle speed. Machine Dab VersatilityIf you run multiple products, the most practical choice is often a machine dab that can adapt without slowing you down. A flexible system should support different day-to-day workflows with minimal changes—so you can move from one SKU to the next without turning every switch into a long setup. When evaluating versatility, look at the range of supported fill volumes, compatibility with common hardware formats (carts, pods, and disposables), and whether the fixtures/trays/jigs are adjustable or easy to swap. It’s also a plus if the machine can handle viscosity changes with small tweaks—rather than requiring a full reconfiguration whenever the oil texture shifts. If you change products often, prioritize quick-change tooling, the option to save and recall settings/recipes (when available), and short, repeatable setup routines that help reduce operator error and keep changeovers consistent. Manufacturer SupportSupport can be just as important as the spec sheet—especially when you’re scaling production and uptime becomes critical. With strong manufacturer support, you can troubleshoot faster, keep output consistent, and avoid unnecessary downtime that eats into your schedule. Look for vendors that provide clear documentation (operation, cleaning, maintenance), dependable spare-parts availability with reasonable lead times, responsive troubleshooting (remote guidance and service options), operator onboarding/training, and straightforward warranty terms. A few smart questions to ask before you buy:What are the most common wear parts, and how often are they typically replaced?What’s included in the accessory kit (spare needles, O-rings, fuses, tools, etc.)?How is calibration handled, and how long does it usually take? After purchase, what does support look like—response time, channels, and the service process? A Longwill dab filling machine is a fully automatic platform built for production efficiency. Automation helps reduce operator variation, improve repeatability, and support higher throughput—while responsive Longwill support and parts availability help keep the system running smoothly as your volume grows. With proper onboarding, ready-to-ship spares, and reliable assistance, it’s easier to maintain consistent performance across shifts and scale confidently as your product line expands. ConclusionA well-matched dab filling machine should make production more predictable: smoother flow, cleaner cut-offs, tighter dosing, faster changeovers, and fewer interruptions during long runs. As you compare options, prioritize the fundamentals—viscosity control, adjustable heating, the right pumping method, compatible materials, and easy maintenance—then choose a platform that can scale with your output and product lineup.