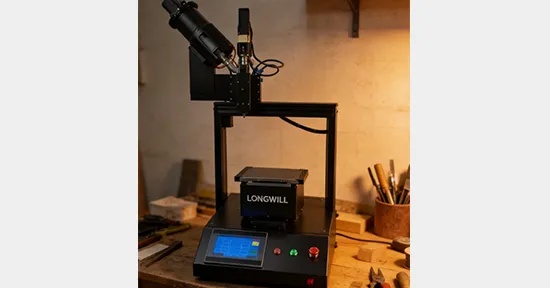

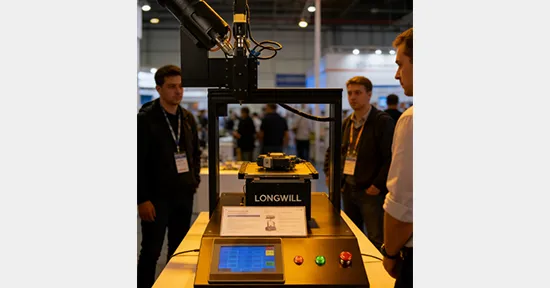

Dab Filling Machine Safety: The Complete Process

This guide details each essential phase of operating a dab filling machine, from setup to daily maintenance. It provides operators with a clear, actionable framework to perform tasks safely and efficiently, helping to prevent common errors and ensure consistent, high-quality filling results.

Dab Machine Setup: Preparing Materials and Workspace

1. Material Readiness & Pre-Filling Protocol

Achieving Uniform Consistency

A critical first step in operating your dab machine is to ensure your concentrate is perfectly homogeneous. Vigorously stir or mix the material to eliminate all air pockets and achieve a smooth, even texture. Trapped bubbles will disrupt the machine's metering accuracy, leading to under-filled or inconsistent products that fail to meet quality standards.

Temperature Conditioning

For the dab filling machine to function efficiently, the concentrate often needs to be brought to an ideal working temperature before loading. Pre-warming the material to its target range (commonly 40-60°C) lowers its viscosity. This conditioning step reduces strain on the machine's mechanisms and promotes a steady, reliable material flow from the first unit to the last.

Preparing Containers

Every container destined for filling—jars, cartridges, or pods—must be prepared to a high standard of cleanliness. They should be meticulously washed, fully dried, and inspected to be free of any particulate matter. Impurities can compromise the end product's purity and are a common cause of clogging in the machine's precision dispensing tips.

2. Configuring the Workspace

Ensuring Adequate Airflow

Maintaining proper ventilation is a fundamental safety measure for any filling station. The work area must be designed with enough air exchange or targeted extraction to handle any subtle vapors generated as concentrates are heated during the machine's operation. This safeguards air quality and ensures a healthier atmosphere for personnel.

Stabilizing Ambient Conditions

Consistent filling results depend on a controlled workspace environment. Aim to keep the room temperature stable, ideally within 20-25°C, and manage humidity levels. Avoiding high-moisture conditions is important to protect the electrical systems of your equipment and to prevent moisture-sensitive concentrates from altering their properties.

Maintaining a Controlled Zone

Dedicating a specific area as a clean zone for your dab making machine is key to minimizing external contamination. Restrict non-essential activity in this space to limit airborne dust. Surfaces should be kept clean and be made of non-porous, easy-to-sanitize materials to uphold a controlled and professional operation.

Dab Making Machine Setup and Calibration: The Foundation of Safe Operation

1. Initial Dab Making Machine Safety Verification

Verifying Electrical Integrity

Prior to activating your machine dab, conduct a complete check of its electrical system. Confirm the power source is reliable, inspect all wiring for integrity, and verify that the unit is correctly grounded. This routine is essential for preventing potential electrical faults during operation.

Assessing Mechanical Components

Carefully examine all mechanical elements, including pneumatic actuators and slide rails, to ensure they move freely without binding. Be alert for any atypical sounds that could signal mechanical issues, and remove any items that might interfere with the machine’s normal motion path.

Temperature System Calibration

Accurate temperature calibration is fundamental for reliable performance. Using a certified reference thermometer, compare the actual temperatures at key points—the material hopper, delivery lines, and dispensing nozzle—against the machine's control panel readings. Consistent calibration maintains process accuracy and safeguards product quality.

2. Process Parameter Setup and Validation

Establishing Temperature Profiles

Configure the independent temperature zones of your machine dab to match the thermal requirements of your specific concentrate. Initiating heat at the lower spectrum of the recommended window and slowly ramping up helps avoid sudden thermal stress on the material, which can preserve its properties and prevent unwanted bubbling or degradation.

Calibrating for Precise Dosing

Enter the desired fill weight into the machine’s interface. To validate accuracy, execute several test cycles, collecting and weighing the dispensed material on a precision scale. Iteratively adjust the settings until the results reliably meet your specified weight tolerance (e.g., ±1%). This diligent calibration is critical for ensuring consistent portioning.

Optimizing Motion and Flow Settings

Tailor the machine's operational dynamics—such as the nozzle travel speed and the rate of material discharge—to the viscosity of your concentrate and the design of your container. Well-adjusted motion profiles are key to achieving neat, complete fills without issues like splatter, webbing, or uneven distribution, streamlining your production process.

Standardized Operating Procedure for Weed Wax Machines

1.Loading the Concentrate

Carefully transfer your pre-conditioned material into the hopper of the weed wax machine using a steady, controlled pouring technique. This helps minimize turbulence and prevents air bubbles from being introduced—both critical for ensuring accurate dosing and a consistent end product. Once loaded, promptly secure the hopper lid to maintain optimal temperature and protect the material from external contaminants.

2.Filling Cycle Operations

Before starting a full production batch, always perform a first-article verification. Run the dab filling machine to produce 3–5 test units, then immediately weigh and visually inspect them. This confirms that fill weight meets the target specification and that the output is free of defects, validating that all system parameters are set correctly.

During the filling run, carry out consistent quality checks. Sample units periodically—for example, every 30 minutes—to verify fill weight and check for issues such as bubbles or incomplete fills. At the same time, continuously monitor the temperature readings across all heating zones. Any significant or sustained deviation should prompt an immediate pause to identify and address the cause.

If a nozzle clog or inconsistent filling occurs, stop the machine right away. Clear blockages using the appropriate pre-warmed cleaning tools designed for the equipment. Never attempt to clear a clog by hand while the machine is running or when components are still hot.

3.Mandatory System Cleaning

Once a batch is finished or when switching between different concentrate types, perform a complete and immediate system clean-out. This step is essential to prevent cross-contamination between product batches, ensuring each product maintains its intended purity and flavor integrity.

Dab Filling Machine Maintenance: Cleaning, Upkeep, and Safety Readiness

1. Daily Cleaning Protocol

Maintaining a consistent daily cleaning routine is vital for your dab machine’s performance and product integrity. Begin by flushing the hopper, supply lines, and dispensing nozzle with a food-grade solvent like ethanol while the unit is still warm, allowing residual concentrate to dissolve easily. For persistent buildup, periodically disassemble components such as nozzles and seals for ultrasonic cleaning. After cleaning, ensure all parts and internal passages are fully dry before reassembly to prevent operational issues in subsequent production cycles.

2. Preventive Maintenance Schedule

Adhering to a regular maintenance schedule helps extend the lifespan of your filling equipment and ensures consistent output. This includes routinely inspecting and tightening mechanical fasteners and electrical connections that can loosen over time. Follow a usage-based plan to replace wear items—such as seals, diaphragms, and tubing—before they compromise performance. Keeping a detailed maintenance log supports equipment tracking, aids in scheduling future service, and assists with quality assurance documentation.

3. Emergency Preparedness Plan

Preparedness is key to managing unexpected situations safely and efficiently. Confirm that all operators know where the emergency stop controls are located and understand how to use them, testing these functions periodically. Ensure that appropriate safety equipment—including a first-aid kit and a properly rated fire extinguisher—is kept accessible near the work area, and that staff are trained in its use. Establish and periodically review straightforward response protocols for common minor incidents, such as small concentrate spills or minor thermal contact, to enable quick and calm resolution without escalation.

Read more:

https://longwillmachinery.com/Blog/how-does-a-dab-filling-machine-work.html

Conclusion

Mastering the operational techniques of your filling equipment is just the beginning. Internalizing safety and standardization into daily practice is the cornerstone of achieving long-term, reliable performance and commercial success.