THC vs CBD Cartridge Filling Machines: Key Differences 2025

This guide breaks down the key product differences, regulatory factors, and technical considerations that set THC and CBD cartridge filling machine apart—helping producers invest in solutions tailored to their specific production needs.

1.Product Differences & Their Impact on Cartridge Filling Machines

At first glance, THC and CBD oils may appear similar, but their unique physical properties create distinct technical demands for cartridge filling equipment. Understanding these differences is critical to selecting machines that deliver consistent product quality, high efficiency, and regulatory compliance.

1.1 Key Physical Differences at a Glance

Attribute | CBD Oils | THC Oils (Concentrates, Live Resin, etc.) |

Viscosity | Typically low to moderate, more fluid | High viscosity, thicker consistency, variable textures |

Temperature Stability | Stable across moderate heat ranges | Heat-sensitive, especially terpene-rich or delicate oils |

Dosing Sensitivity | High accuracy preferred, less strict | Requires precise, sub-milliliter dosing to prevent product loss |

These factors directly influence pump selection, heating system design, and automation configurations for filling machines.

1.2 Viscosity & Flow Behavior

CBD disposable cartridges, particularly isolates and broad-spectrum formulas, flow easily and maintain stable consistency, simplifying high-speed filling and reducing technical complexity.

THC oils, especially live resin or terpene-enriched extracts, are much thicker, requiring advanced heating control and pressure-assisted mechanisms to maintain a stable flow during filling.

1.3 Heat Sensitivity Considerations

CBD oils tolerate a broader temperature range, allowing for faster filling cycles with moderate thermal management.

THC concentrates degrade quickly under excessive heat, necessitating machines with precise, low-temperature heating zones to preserve cannabinoids and terpenes.

1.4 Accuracy Requirements

While dosing consistency is essential for all cartridges, THC production lines operate under tighter regulatory and financial constraints, demanding micro-precision to avoid product loss and ensure every unit meets legal potency standards.

The physical nature of the oil dictates every aspect of equipment design—from pump type to heating configuration. Manufacturers must align these technical specifications with their product formulations to maintain efficiency and avoid costly quality issues.

Unlock the potential of your CBD production with the best cartridge filling machines—Read our comprehensive guide to optimize your productivity.

2.Regulatory and Compliance Considerations

In the cannabis industry, regulatory compliance isn't just a formality—it's a critical factor shaping how filling equipment is designed, selected, and operated. The requirements for THC and CBD disposable cartridges differ significantly across markets, directly impacting technical configurations, production processes, and ultimately, business viability.

2.1 CBD Disposable Carts: Still Regulated, But More Flexible

While CBD disposable cartridges generally face fewer restrictions, especially for hemp-derived products with minimal THC content, manufacturers cannot overlook critical regulatory factors:

Accurate Dosing & Labeling

Even in wellness or over-the-counter markets, consistent oil volume and ingredient disclosure are mandatory. Equipment should maintain reliable dosing tolerances, particularly for full-spectrum CBD products that contain legal trace amounts of THC.

THC Threshold Sensitivity

Products approaching regulatory THC limits (e.g., 0.3% in the U.S.) require heightened quality control during filling. Machines must support precise dosing to prevent batch failures due to inadvertent THC overages, which can result in costly rework or product seizure.

Scalability & Multi-Product Adaptability

Many CBD disposable carts diversify into THC markets or operate mixed production lines. As such, selecting equipment with modular configurations and compliance-ready features ensures operational flexibility across both product categories without excessive capital investment.

2.2 THC Production: Tighter Oversight & Operational Demands

Compared to CBD, THC cartridges fall under far stricter legal controls, especially in regions like North America, Europe, and parts of Oceania, where recreational or medicinal cannabis markets are highly regulated. Key compliance points include:

Dosing Accuracy Requirements

THC product potency and dosage levels are tightly controlled by regulatory bodies. Filling machines must deliver verifiable, highly consistent fill volumes to meet legal standards and avoid product recalls or penalties. Equipment with integrated precision dosing systems—such as positive displacement pumps—has become a baseline expectation.

Product Integrity & Safety Features

Many jurisdictions mandate the use of tamper-evident closures, nitrogen pressurization, and fully enclosed, sanitary filling environments to minimize oxidation, microbial contamination, and unauthorized product alteration.

Machines lacking these safeguards may not qualify for THC production certification, limiting market access.

Traceability & Batch Documentation

THC product lines must integrate robust batch tracking, serialization, and automated record-keeping, often enforced through audits or regulatory inspections. Modern filling systems must support this level of traceability to ensure compliance at scale.

2.3 Conclusion: Equipment Selection Must Align with Legal Realities

Filling machines that fail to meet the specific regulatory and hygiene standards for THC or CBD products risk production delays, legal repercussions, and market exclusion.

To mitigate these risks, forward-thinking manufacturers invest in versatile, compliance-driven filling systems designed to:

Support high-precision dosing across varying oil viscosities

Integrate closed-loop, sanitary filling processes suitable for regulated products

Enable traceability, batch documentation, and real-time quality control

Offer modularity to switch between THC, CBD, or hybrid production lines

In an evolving global cannabis market, regulatory alignment isn't optional—it’s the foundation for efficient, scalable, and legally secure cartridge production.

2.4 Product Source Matters: Hemp vs. Marijuana and Its Impact on Disposable Carts

When it comes to disposable cartridge for CBD or THC oils, the source of the raw material—whether extracted from hemp or marijuana—plays a critical role in determining both equipment requirements and regulatory expectations.

Hemp-derived oils, which are federally classified by containing no more than 0.3% THC (according to U.S. standards), dominate wellness, nutraceutical, and skincare markets. Although CBD cartridges made from hemp typically face fewer restrictions, manufacturers cannot disregard compliance entirely. Full-spectrum or broad-spectrum CBD products, for instance, may contain trace levels of THC that approach legal limits, making precise dosing and strict batch control essential to avoid regulatory violations.

In contrast, marijuana-derived oils, naturally higher in THC, are subject to far more rigorous oversight. Producing THC cartridges for medical or recreational use demands that filling processes meet elevated standards, including:

Exceptional dosing accuracy to maintain consistent potency and prevent exceeding allowable THC concentrations

Tamper-evident, child-resistant, and compliant packaging to align with consumer safety mandates

Comprehensive traceability and batch tracking to satisfy audit and reporting requirements

It is important to note that equipment engineered exclusively for hemp-based CBD disposable cartridge production may not fulfill the technical or compliance demands of marijuana-based THC filling, especially in jurisdictions with strict cannabis market controls.

As regulatory frameworks evolve, manufacturers are increasingly turning to versatile, modular filling systems capable of handling both hemp and marijuana oils. These adaptive machines not only accommodate varying viscosities and cannabinoid profiles but also ensure production remains compliant across diverse legal environments.

In a competitive, highly-regulated market, aligning filling operations with both product source and regional compliance standards is no longer optional—it’s essential for scalable, legally sound cartridge manufacturing.

3.Technical Distinctions in THC vs. CBD Cartridge Filling Equipment

Modern cartridge filling machines are engineered with specialized technologies to address the distinct production challenges of CBD and THC products. From managing oil viscosity to achieving dosing precision, the technical configuration of each system must align with product composition, regulatory expectations, and operational priorities.

3.1 Heating & Thermal Management

CBD Filling Solutions

CBD oils—particularly isolates, broad-spectrum blends, and lower-viscosity distillates—require simplified heating configurations. Machines designed for AIO disposables prioritize energy-efficient thermal systems, maintaining oil consistency without excessive complexity or operational cost. This streamlined approach supports high-throughput production while preserving oil quality.

Unlike higher-viscosity concentrates such as live resin or rosin, which demand more advanced handling systems, these lower-viscosity CBD oils allow for more efficient processing. Purpose-engineered equipment leverages optimized heating and flow control to reduce material waste, improve dosing accuracy, and simplify operation—making it well-suited for automated filling and sealing lines with minimal manual intervention.

THC-Focused Systems

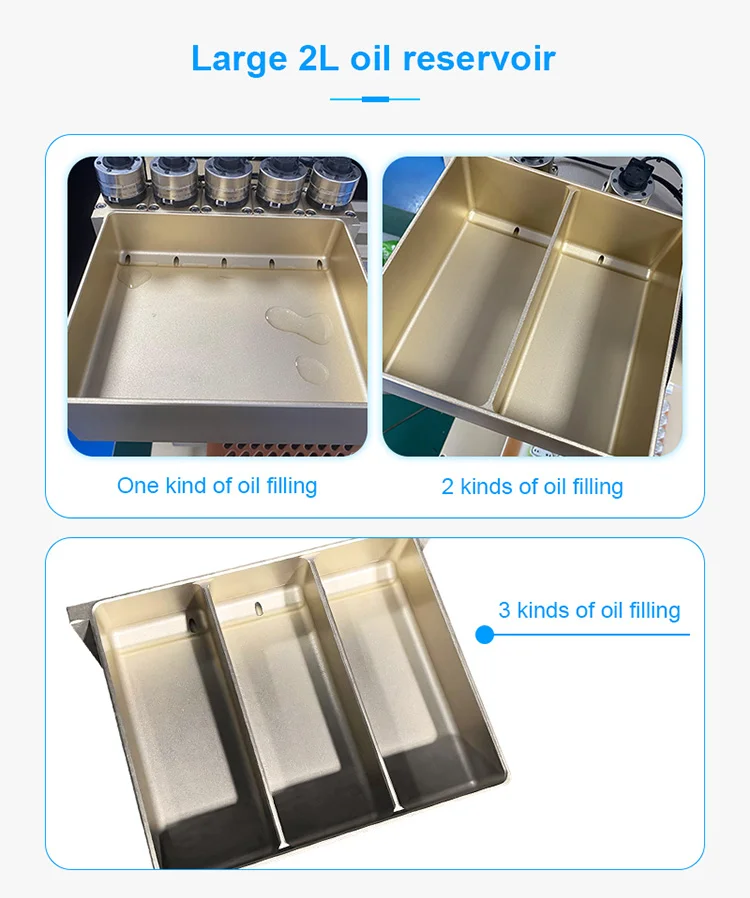

In contrast, high-viscosity THC concentrates—such as live resin, terpene-rich distillates, or full-spectrum oils—demand advanced thermal control. Leading filling machines incorporate multi-zone, independently adjustable heating along oil reservoirs, tubing, and filling nozzles. This ensures stable flow, prevents clogging, and protects sensitive cannabinoids and terpenes from heat degradation during filling.

3.2 Dosing & Pump Technologies: Key Differences at a Glance

Specification | CBD Cartridge Filling Lines | THC Cartridge Filling Lines |

Pump Type | High-speed gear, peristaltic, or standard piston pumps | Positive displacement or rod-valve precision systems |

Dosing Accuracy Tolerance | Precise dosing preferred, with greater tolerance flexibility | High precision (sub-milliliter), essential for potency control |

Viscosity Handling | Optimized for moderate viscosity across broad oil profiles | Engineered for thick, terpene-rich, or complex oils |

For CBD production, particularly in wellness or consumer markets, operational speed and efficiency often take precedence. High-speed pump systems, including gear or peristaltic mechanisms, deliver acceptable dosing accuracy while supporting large batch production at lower costs.

THC oils, however, carry higher potency and economic value, requiring enhanced dosing precision to ensure consistent cannabinoid concentration per cartridge. Positive displacement pumps or rod-valve mechanisms minimize waste, optimize material yield, and meet strict regulatory tolerances.

3.3 Automation, Capping & Nitrogen Integration

AIO Disposables Flexibility

Many CBD cartridge lines—especially those operated by small to mid-sized businesses—utilize semi-automatic or manual capping solutions to balance production costs with acceptable product protection standards. For manufacturers prioritizing agility and batch versatility, this approach provides scalable entry into cartridge production.

THC Production Requirements

THC cartridges, due to higher regulatory scrutiny and product value, often demand fully automated capping systems with tamper-evident mechanisms, nitrogen flushing to minimize oxidation, and enclosed filling environments to prevent contamination. These technologies extend product shelf life, preserve oil integrity, and ensure compliance across regulated markets.

3.4 Equipment Modularity & Multi-Product Adaptability

Many producers today operate hybrid facilities, manufacturing both CBD and THC cartridges across diverse product lines. Leading equipment manufacturers offer modular, adaptable filling systems designed to simplify these transitions.

Modern machines frequently include:

Quick-change nozzle assemblies for different cartridge formats

Adjustable heating modules to handle various oil viscosities

Configurable dosing systems tailored to each product's precision requirements

This modularity enables efficient changeovers between CBD and THC production, reducing downtime, supporting SKU diversity, and eliminating the need for redundant equipment investments.

Learn more:

https://longwillmachinery.com/how-to-clean-and-maintain-a-vape-cartridge-filling-machine.html

https://longwillmachinery.com/what-to-know-before-buying-vape-cartridge-filling-machines.html

https://longwillmachinery.com/best-cart-filling-machine-for-cannabis-oil.html

Conclusion

In the rapidly evolving cannabis market, precision, efficiency, and compliance are non-negotiable. Whether you're filling CBD cartridges for wellness markets or THC products for highly regulated territories, understanding the technical distinctions between these product categories is essential.